Today we submitted our assignments and ruby, kate, Laura, Julia, Zara and I went onto the oval and tried our trebuchet by replacing it on a plank of wood run way.

We found that giving it a push and releasing it at the end gave it the larger distance. Ruby and ours ended up going the furtherest which we are proud of.

Sunday 11 November 2012

Monday 5 November 2012

Blog Update

Today Mr Ward went over how to do the written part of the assessment. He talked us through the entire theory element of the assessment, calculating the PE, Velocity and KE. I found that by calculating the final KE, it really helped for writing the end of unit evaluation and I re-worte my evaluation based on my new calculations.

So all I have to do now is print the assessment and it will be ready to hand in.

So all I have to do now is print the assessment and it will be ready to hand in.

Sunday 4 November 2012

Blog update

Today ruby and I went into the workshop and I just added a bit of reinforcement to the arm.

I ten found some string and used that for the release contraption because, they used them in old times and it is just really fun to cut the rope and let it fling away. I finished my calculations and my assignment is ready to priny

I ten found some string and used that for the release contraption because, they used them in old times and it is just really fun to cut the rope and let it fling away. I finished my calculations and my assignment is ready to priny

Friday 2 November 2012

Blog update

Last lesson ruby and I tested our trebuchet and took recordings for our handed in assessment. We went to outside boarders and the chapel because we though that that would be the flattest place and we could get an accurate shot from that. Our first two releases went in the 10m mark but the other 3 (we would release the ball 5 times to get a good average) it would a only go around 5m because it would crash into the bushes.

The results were:

Average Distance: 7564.6mm

Average Time: 2.116sec

Mass: 145.4g

We still need to record the height but I will have to ask mr ward about that and where we measure it from. We decided to to re record the last 3 distances because it is part of the assessment and it will give us something to talk about in he evaluation.

The results were:

Average Distance: 7564.6mm

Average Time: 2.116sec

Mass: 145.4g

We still need to record the height but I will have to ask mr ward about that and where we measure it from. We decided to to re record the last 3 distances because it is part of the assessment and it will give us something to talk about in he evaluation.

Monday 29 October 2012

Blog Update

Today ruby and I got our catapult finished. It was really good. We started off by adjusting the axel at the top so that the dimensions fitted the trebuchet. We then worked on attaching the cup to the end of the propellor. We first tried making a stand for it but then Mr ward said it should be fine how it is. With the help of Mr Ward we then screwed holes in the bottom and this took a bit of adjusting so that the Asclepius in which the wheels are to rotate off can rotate. But after that, it was just a press fit of the wheels and then the catapult was ready.

First using a 1kg weight that was hooked to our swing, we propelled the ball from outside the classroom and it reached about the drains. We then advanced and added a 2kg weight and the ball went further. I think next lesson we will just reinforce the pole at the end closest to the axel because the wood is beginning to split. But after that then we will do our recordings and I will video it so I can not step by step, the process in which the catapult takes.

First using a 1kg weight that was hooked to our swing, we propelled the ball from outside the classroom and it reached about the drains. We then advanced and added a 2kg weight and the ball went further. I think next lesson we will just reinforce the pole at the end closest to the axel because the wood is beginning to split. But after that then we will do our recordings and I will video it so I can not step by step, the process in which the catapult takes.

Sunday 28 October 2012

Blog Update

Today ruby and I got straight into the workshop. But before we did that we made sure that we could do tomorrow lunchtime to get more of it done so that we had plenty of time to get the whole assessment done before the due date.

We started off by finishing the extenctions and support to the top of the A-Frame, which glued well. We then got Mr. Ward to help, and Ruby drilled a hole in our sling, this was a factor that made it line up with the bottom of the A-frame, not the full catapult end. This would allow us to have more force pulling down on the weight end of the sling.

Mr Ward then drilled a hole through the other A-frame and we managed to get the whole top part lined up with not too many issues due to the un-allignment of the frames.

I then drilled a hole through the bottom of the sling where we would hang our weight off. I was nervous but I was able to do it fairly well and it was good that I was made to do it under controlled conditions so it was harder for me to do something wrong. I also hammered the rod through that Mr Ward measured out to be a press fit and then I sanded it smooth.

Ruby then had the idea to cut a wheel in half and use it for the pin holder. It looks really good but we will finish it later when we know the full dimentions of our cup.

Wednesday 24 October 2012

Blog update

Today we glued the two a frames to the plank connecting them at the bottom. Once we did that, mr ward pointed out that our a frames were not even because of a tilt or not properly measured middle rod in the a frame. Mr ward started by drilling a hole through the top but then it snapped. Mr ward then showed how to add the reinforcements I the side so we are working on that now

Monday 22 October 2012

Design

Today in design mr ward was away do we did theory. I managed to put the timeline onto an actually timeline and I wrote out the definition for PE and got all the rest of the assessment ready. So when I have the information, I can just write it in.

Wednesday 17 October 2012

Blog update

Today we went ahead with making the A frame. After pushing and gluing the vertical side into the horizontal piece of wood that utter brilliantly.

we measured up the wooden frames for the long diagonal frame. Though we measured it out to what we thought should be perfect - it didn't end up that way. So when we glued one of the sides on we had to add a thinner peice of wood to it so it would e more secure.

we measured up the wooden frames for the long diagonal frame. Though we measured it out to what we thought should be perfect - it didn't end up that way. So when we glued one of the sides on we had to add a thinner peice of wood to it so it would e more secure.

Monday 15 October 2012

Blog update

Today ruby and I ruled up (this time because last time it was a last minute rush because it was a mistake in progress). So we added another block of wood across the frame for the other frame. We also reinforced bits and prices with nails so that te Redfin is up to date. We measured up and cut one of the other joints to the frame and it fitted perfectly. We went to the other side but didn't have time to check it fits.

Uploaded are the pictures from lat lesson

Uploaded are the pictures from lat lesson

Sunday 14 October 2012

Blog Update

Today in design Ruby and I sanded down or connectors and glued them in. Now the connectors din't fit right so we had to nail them in at the same time. This was an unplanned process so the first nail ended up coming out the other side, rather than through the center.

However by the end of the lesson we had all the - for the A frame set into both frames and for the first, we also secured it with another piece of wood (glued) to keep it together and to keep it straight. We also made reinforcements to the tops of both A frames and the bottom of one of the A frames. I have my time line ready for my assessment, however I could not find the full assessment schedule on blackboard again so I have emailed Mr. Ward regarding that matter.

However by the end of the lesson we had all the - for the A frame set into both frames and for the first, we also secured it with another piece of wood (glued) to keep it together and to keep it straight. We also made reinforcements to the tops of both A frames and the bottom of one of the A frames. I have my time line ready for my assessment, however I could not find the full assessment schedule on blackboard again so I have emailed Mr. Ward regarding that matter.

Wednesday 10 October 2012

Blog Update

Today Ruby was here and we continued with our - of the A frame. By the end of the lesson we had the two sides for each glued together so they can be attacted properly to the fame. This lesson I also traced out reinfrocements for the top of the frame. What I have planned to do before we finish the A frame is to

- enforce < > in with screws

- Renforce base with pva glued wood

- drill hole for the axel to pass through

etc...

i also broke the drill saw today and learnt to saw a few millimeters away from the cut line and then sand the rest (this has been really helpful)

I have started my timeline

Lined

Timeline of Trebuchet

· 3-5bc: The Chinese were thought to have invented the first

trebuchet (Huihui Pao) which, in design, was very similar to a sling, with

15-45 men used as the counterweight.

· 300ad: Greek and

Roman (Soldiers of Piliip of Macedonia created their ballistas (a different

form of trebuchet) which design was similar to a crossbow and is thought to be

the primiary inspiration for the catapult/trebuchet. Difference is that ballistas used two wooden arms rather than one

· 350ad: Romans created mangoles which was similar to the ballistas

however they only had one wodden arm enabling them to hurl stronger and sharper

objects at a greater speed.

· 965 c: First recorded hand-trebuchet in Greece.

· 6th c: “balliustae revolving in both directions”

this appeared in Byzatium

· 12th c:

French created the trebuchet which turned to be the true siege engine of mass

destruction and at the time it’s power and force was unmatched. It used only

one wooden arm which rested on a pivot point. Because the point was used as a

leaver, the object could be hurdled at a much greater spped and strength.

· Middle Ages:

catapults were the major siege weapons because of there extreme effectiveness

in battles. As history went on, the catapult evolved, capable of more damage.

The catapults were used to fire projectiles (as much as three hundred pounds)

as well as bodies of people and animals who have died of a disease, into the castle

walls.

· 1097: Emperor Alexios I Kommenos in the Siege of

Nicaea was reported to have invented a new form of trebuchet.

· 1211ad: The siege

of Castelnaudry was the first time that a trebuchet is mentioned.

· 1124: The Crusaders used great siege engines for

the Second Siege of Tyre in Lebanon. It is believed that these great siege

engines were counterweight driven trebuchets.

· 1187: The first pictorial evidence of counterweight

driven trebuchets appeared in a military manual written for the military leader

Saladin.

· 1191: for the

siege of Acre two large trebuchets were used by Philip II

· 1268 First recorded Chinese counterweight

trebuchets in the Mongol siege to Francheg and Ziangyang.

· 1304: A giant trebuchet named “warwold” was created

for the English army

· 1475: The introduction of gunpowder caused less

need for trebuchets over cannons however the trebuchet was still used in the

siege of Burgos

· 1779: When British forces were defending Gibraltar

the constructed a trebuchet because their cannons were unable to fire long

enough.

Tuesday 9 October 2012

Blog Update

Today Ruby was away so I worked by myself in the workshop today. I started straight away and continued working on the materials from last term. Today I ruled up more connections to go across the middle of the A-Frame. To ensure stability within the frame we are having two sides to this connection. So this lesson I ruled up the markings and used the drill saw and started cutting them to shape.

Sunday 16 September 2012

Blog update

Today we went ahead with making the A frame. After pushing and gluing the vertical side into the horizontal piece of wood that utter brilliantly.

we measured up the wooden frames for the long diagonal frame. Though we measured it out to what we thought should be perfect - it didn't end up that way. So when we glued one of the sides on we had to add a thinner peice of wood to it so it would e more secure.

we measured up the wooden frames for the long diagonal frame. Though we measured it out to what we thought should be perfect - it didn't end up that way. So when we glued one of the sides on we had to add a thinner peice of wood to it so it would e more secure.

Wednesday 12 September 2012

Blog Update

I'm going to try my blog in a different layout, see if it works:

Lessons Learned

Lessons Learned

- That for major holds in the A frame, to nail the fittings in with the PVA glue so that the holds will hold the parts together

- Accross the base and other major joins in the A-frame, have another peice of timber glued accross in order to fully secure the frame.

- Have thicker blocks to hold the two A-frames together at the same distance appart.

- Use pre-made wheels (equipment available)

- Watch the length of the leaver so that the A-Frame is long enough to compact with the length of it. -Mr Ward is having to change his

- Mr Ward is good at cutting big pieces of wood to a good measurement

What we did this lesson

Today we started building the T shape for the A frame. We are going to use the box fit and we cut of the box needed for this. We have it ready to fit even through it could have been more accurate. Next lesson we will be able to glue it.

I am still not overly confident with the machines but i guess that will come with experience.

Tuesday 11 September 2012

Blog Update

Yesterday Mr Ward showed us how to make a house fit in which it is one point in which is suppressed and then with the added glue, it will make a very tight and secure fit.

Ruby and I went on to creating the dimentions to our frame. We are planning to go into the workshop in the next possible lesson

Ruby and I went on to creating the dimentions to our frame. We are planning to go into the workshop in the next possible lesson

Monday 10 September 2012

Tips From http://www.butlercc.edu/engineering/en115/en115_basic_treb_design.cfm

Object

|

Design guidelines

|

Material

|

|---|---|---|

| Counterweight | 75 to 100 times heavier than projectile | should be adjustable |

| Arm | angle should be about 45 degrees when cocked; upper part of arm should be 3 to 5 times longer than the lower end | pvc pipe |

| Base and framework | must be heavy enough to support arm and counterweight and for precision, yet light enough to have a high material efficiency | pvc pipe |

| Sling or rope | should be slightly shorter than upper part of the throwing arm (for starters, that is); too short will release the projectile too early, higher trajectory; too long will drag the ground, lower trajectory | any material |

| Sling release pin | a more hooked prong will hold the sling loop longer than a straighter one. ie a prong less hooked or in line with beam gives an earlier release, higher trajectory;a prong more hooked or forward-pointing gives a later release, flatter trajectory | metal or other material |

| Projectile | a heavier projectile tends to pull the loop off the prong earlier than a lighter projectile does. heavy projectile gives earlier release, higher trajectory; light projectile gives later release, flatter trajectory | tennis ball-provided |

| Trigger | you need some way to release the projectile in a repeatable way | any material |

| Trough | the projectile needs to slide down some type of guide; friction will be important here | any material |

| *Base wheels-optional | wheels added to the base may increase distance; repeatability(? ) | any material |

Blog Update

Today we went over the new assessment. Mr Ward went over his planning for his trechubet and and how it is to work. There seem to be alot of ways in which to approach this unit, some trechubets are sturdied not on wheels but on an axel. However I think having wheels will make the trechubet more stable than if it were held by just a few wheels.

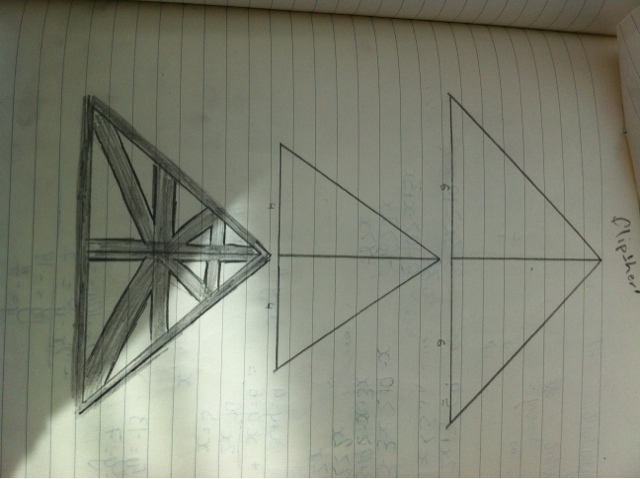

Ruby and I got to work on our planning and with images of trechubets open, I worked out a design for the framing of our catapult. I rember learning somewhere that triangles are the sturdiest shape to build a from so I took that Idea and made the framing of the trechubet many trianges. We worked on the height to length ratio also.

Ruby and I got to work on our planning and with images of trechubets open, I worked out a design for the framing of our catapult. I rember learning somewhere that triangles are the sturdiest shape to build a from so I took that Idea and made the framing of the trechubet many trianges. We worked on the height to length ratio also.

Thursday 6 September 2012

Blog Update

This week was a good fun one. In our first lesson we had our last adjustments to our kart and i just adjusted the glue to make sure the wire at the front stuck. We also discussed what to do for our next assesment. Zara wanted to build some sort of wood work and we all wanted to make rockets, though I had allready done that in year 5 so I wasn't as keen. But then I had the idea to make a catapult (partly because I was thinking of Lord of the Rings and other because my brother had just found a nerf gun). But anyway, the idea was accepted and everyone seemed keen.

The race day, well I got kicked out on the first round -very close through - and I lost to Amber who won so, well, luck of the draw. I was on timer and it kept me busy so I was happy.

Last lesson we discussed more on our new unit which is building a trechuet (catapult). It looks really exciting and I am actually really keen to do the history about it because medieval history is pretty much my favourite era to look at.

I will be working with ruby and we started researching designs for our machine and we have found some variables in the design

The race day, well I got kicked out on the first round -very close through - and I lost to Amber who won so, well, luck of the draw. I was on timer and it kept me busy so I was happy.

Last lesson we discussed more on our new unit which is building a trechuet (catapult). It looks really exciting and I am actually really keen to do the history about it because medieval history is pretty much my favourite era to look at.

I will be working with ruby and we started researching designs for our machine and we have found some variables in the design

- wheels or no wheels (we already know from a video that Mr Ward showed us that it works better with wheels because it increases the thrust of the object fired

- The holder can be either a spoon shape, a "sling-shot" type shape, of a netted basket

- How much scaffolding is on the model

- what is used as the weigh (usually it is a box that the weight could be changed)

- length of the rope

Sunday 2 September 2012

Blog Update

Today if the day before the kart racing and my kart is just getting slower and slower. It started off at an origional speed being 2.645 and now the times aren't even clearing 3 seconds. I changed the batteries but it doesn't make much of a difference. I find it is because the kart is beginning to go off course because from what i remember the wires were tighter at teh start, now my kart is travelling to other sides of the course.

But then again it could be any other feature aspect of the kart that could be deterioating.

But then again it could be any other feature aspect of the kart that could be deterioating.

Monday 27 August 2012

Blog Update

Today Mr. Ward went over the equations needed for the assesment, which was good to be refreshed on. I started the lesson by going into the workshop and weighing my kart and giving it one last run.

The average for my kart is about 2.7seconds, though my best was 2.465. Afterwards I went back into the classroom and did the rest of my calculations and added them to my assesment. I also got my progress pictures from my blog and put them onto my assessment to hand in.

I will print my assessment tonight

The average for my kart is about 2.7seconds, though my best was 2.465. Afterwards I went back into the classroom and did the rest of my calculations and added them to my assesment. I also got my progress pictures from my blog and put them onto my assessment to hand in.

I will print my assessment tonight

Sunday 26 August 2012

Blog update

Today was purely racing. It started off really good. A time of 2.65!! But then I added a price of plastic at the front to supposidally reduce the air resistance but I resulted in increasing the time by .4 of a second.

I have also noticed that the front wheels aren't fully connecting with the track and are sometimes spinning

I have also noticed that the front wheels aren't fully connecting with the track and are sometimes spinning

Thursday 23 August 2012

Blog Update

Today I finished my kart. I glued the switch on and front wheels and with a push, the kart stayed on a straight course. I soldered the wires together, this time I was more successful doing it myself. I then glued the copper wires onto the front and end of the kart.

Then it was time to give the kart a test run, I put a little grease on the copper wires, in order to reduce friction between the wires and the fishing line. On my first run of the kart, it didn't time, but it looked faster than I expected so I was excitied. When I tested it for a second time, I got the time

= 2.795 seconds!

Under 3 seconds on my first run!!! After, I discussed with Mr. Ward why we think that having the motor on the bottom imporves the time. I thought it was a simple matter of just reducing the air resistance and adding weight to the wheels (so they do not spin). But Mr. Ward had a good theory in that, having it on the bottom actually pushes away from the axel and therefore reduces the friction.

I believe ways in which i can make my kart go faster is to

Then it was time to give the kart a test run, I put a little grease on the copper wires, in order to reduce friction between the wires and the fishing line. On my first run of the kart, it didn't time, but it looked faster than I expected so I was excitied. When I tested it for a second time, I got the time

= 2.795 seconds!

Under 3 seconds on my first run!!! After, I discussed with Mr. Ward why we think that having the motor on the bottom imporves the time. I thought it was a simple matter of just reducing the air resistance and adding weight to the wheels (so they do not spin). But Mr. Ward had a good theory in that, having it on the bottom actually pushes away from the axel and therefore reduces the friction.

I believe ways in which i can make my kart go faster is to

- grease between the gears and wheel joints

- add a peice of plastic on the front to the top of the battery to reduce air resistance

- sand the wheels

I will also need to measure the track and weigh my kart in order to get the data needed to finish my handed in assessment.

I am slowly reducing the amount of writing I have for my assesment. I have taken out all example non-relevant to the brief (even though there are more cases of friction than what effects the brief) and I am trying to reduce the materials list.

Tuesday 21 August 2012

Assignment update

This is my assignment so far. I am having extreme diffuculity keeping ti under the word limit and I have not even done my reflections

Velocity

is calculated by the equation, change in distance over change in time. Or

written as;

Velocity

is calculated by the equation, change in distance over change in time. Or

written as;

Mr. Ward Week

7 2012

Amanda

Tauber

Investigate

and Designing

Friction:

Friction is a resistant force and occurs

when any two objects (solid, liquid or gas) come into contact with each other.

If an object is going one way – friction is pulling the object in the other

direction.

Friction can occur between any of the

following;

·

Two solid objects – the wheels of the kart and the surface of

the track, the gear kogs, the cooper wire and the fishing line, the wire

holding the tires together and the plastic tube etc.

·

Solid and Air – (Also known as air resistance), this can

occur anywhere in the direction the kart is travelling, when the kart pushes

forward, the air resistance will be pushing back on it.

·

Solid and Liquid – not as relevant to this design brief but an

example of this could be a person waddling in the water

·

Liquid and Air – once again, not as relevant to this brief,

but you notice this type of friction when water falls over a waterfall and is

turned into spray due to the friction with the air.

Friction is useful for;

·

Grip –the purposeful friction made into the wheels

in order for them to have grip on the floor. This stops the tires from

spinning. But in everyday uses, it is used in most items designed to move and stop

– anything from motorbikes to the grip on shoes.

·

Positive Air

resistance – though not entirely relevant

to this experiment, parachutes and similar inventions use air resistance to

work (to catch the air, allowing the rider to ‘float’)

·

Brakes – though our kart will not come with brakes,

friction is used to slow down and stop transport vehicles, (cars, motorbikes,

trains etc. ) by applying pressure (in simplest form) to the wheel which thus

causes the form of transport to slow down and stop.

Friction is a problem when;

·

The wear between

surfaces causes machernery to wear away and need replacement

·

Friction/air

resistance/drag is a waste of energy in machines for it has to create a

stronger force to counter the friction pushing back on it.

o Also

slows down moving objects

Ways to reduce friction;

·

Lubricating oil and

grease between surfaces

·

Wheels or ball

bearings or polystyrene balls to roll the surfaces past each other

·

Cushions of air (as

in hovercrafts for they avoid the friction with the ground)

·

Streamlined shapes to

keep air resistance at a minimum.

Velocity:

Velocity is the speed in which an object

is moving in relevance to the objective destination. Unlike speed which

describes how fast the object is moving, velocity gives a value on how fast the

object is going from point ‘a’ to point ‘b’

e.g. a car driving 50km/hr north.

A constant velocity must include a

constant speed and constant direction (straight path). Eg. A car is at a

constant speed of 40km/hr and is moving on a straight road – hence it has a

constant velocity

The velocity of an object will

accelerate or decelerate not only when the speed of the object changes, but if

the direction varies. I.e. if a car is turning a corner but, still is at a

speed of 30km/hr the velocity decelerates and then accelerates because the time

it takes to get closer to the objective goal varies as the car goes off the

direct course.

The velocity of my kart is;

Distance =

Time =

Therefore,

V = _/_

=

Kinetic Energy is the energy of

motion, any object that moves contains some amount of kinetic energy. Kinetic

energy is expressed by the equation: KE = ½ x m x v2 . This shows that the value of

kinetic energy relies on the mass and velocity (or speed) of the object.

Acceleration - Perform calculations to determine the average acceleration of your

vehicle.

|

Materials

|

Use

|

Characteristics

|

Properties

|

|

Plywood

|

The ‘chassy’ of my design. It keeps all the other materials used

to power my kart secure.

|

Very light weigh however it is not ‘flimsy’ and does not break

easily. With a power saw, it is easy to c

|

Approximently 4mm thick, 11cm long and a varing width of 4cm –

0.1cm.

|

|

Small gear

|

Attached to the motor, it interlocks with the larger motor,

thus, transferring the electrical energy within the motor into kinetic

energy; spinning the wheels.

|

It is made up of a plastic and the cog has a small hole through

the center of it. This hole is a ‘push fit’ insuring that it is attracted to

the motor.

|

It has 8 indents which interlock with the larger wheel and an

approximate 0.3cm diameter.

|

|

Large Gear

|

Attached to the back Axel, this large gear. Interlocking with

the smaller gear, this large gear turns the wheel.

|

“as above”

|

|

|

Motor with +ive and –ve

wires

|

To covert the electrical energy into kinetic energy

|

It is make of metal with a plastic cap on one end of the motor.

|

Has a metal point that the small cog is attached to. Also has

coloured positive and negative wires, pre soldered to the opposite end.

|

|

X2 Large wheels

|

To transfer the kinetic energy from the motor and use that

energy to drive the kart forward

|

A circular diameter with the grip and tire cap removed. Has an

opening on the inner side. Alowing the axel to press fit – so it does not

slide off.

|

The tire came with a cap and grip tire, but I had removed them.

|

|

x2 small wheels

|

To move the kart across the track.

|

|

|

|

x2 strands of copper

wire

|

To keep the kart running along the track in a straight line

|

The copper wire is dutile, allowing it to be bend and manipulate

into different shapes and forms

|

It only consists of the copper wire

|

|

Battery Pac with +ive and –ve

wires

|

To transfer the chemical energy through to electrical energy

|

Normal characteristics of a x2 battery pac

|

The battery pac and a positive and negative wire.

|

|

x1 Switch with +ive and –ve

wires

|

To have easy access to open and close the circuit.

|

A flick switch.

|

has coloured positive and negative wires, pre soldered to the

opposite end.

|

|

x2 4cm plastic tube

|

To attach the axel to the chassy whilst allowing the axel to

spin

|

A hollow plastic cylinder

|

transparency,

flexibility, elasticity, permeability, water resistant, electrical resistance

|

|

x1 7.2 (approx.) axel

|

To attach each of the two wheels together and to enable the gear

to successfully turn the wheel.

|

Metal cylinder

|

It is hard, ensuring it does not bend easily

|

Planning – A documented series of

ideas showing the development of your final solution.

Sequencing – This is for my final

design (using plywood)

1.

Making the Chassy

a.

Draw the chassy (expressed in image *final* as

shown above in planning) with correct measurements and all lines shown, adding

2mm to each side.

b.

Using the “jigger jagger” cut the shape of the

chassy out.

c.

Sand all sides of the chassy until smooth. Sand

also the front point of the chassy, allowing a smooth rise from the bottom to

the top of the chassy.

2.

Producing the Front

Wheels

a.

Measure and cut the plastic tube and axel to

scale. (note. When cutting the plastic

tube, use pliers to reopen the end of the tube that was closed via the cutting

of the tube)

b.

Remove the wheel caps from the small wheels

c.

Hammer one point of the axel into the first of

the small wheels, slide the plastic tube onto the axel.

d.

Hammer the final small wheel onto the end.

(make sure you leave enough room between the plastic tube and wheels to ensure

that the wheels spin)

e.

Leave for later

3.

Producing the Back

wheels,

a.

Follow steps 2a-c with back wheel measurements

b.

Hammer the large gear on (top hat first). Using

a cog on the side of the workbench and hammering the axel through the gap.

c.

Hammer the other wheel onto the end of the axel

4.

Using hot glue, attach the battery pack to the

very end of the chassy, with both wire’s facing the end of the chassy.

5.

Attaching the wheels

a.

Glue both sets of wheels on by applying a line

of hot glue over the lines ruled onto the chassy as done in step 1a, and attach

the white plastic tube to the hot glue.

b.

Allow to set before gluing the other wheel

6.

Attaching the motor

a.

Apply hot glue to the bottom of the motor

b.

Press the motor onto the bottom of the chassy

and slide the motor until the small gear wheel interlocks with the large gear

wheel

7.

Hot glue the switch to the back of the chassy.

8.

Wiring up the elements

a.

Using the wire cutters, cut the wires to a length

in which the least wire is hanging loose

b.

Using the soldering iron heat up the connection

points between the two wires, once hot, melt some _____ onto the connection

c.

Repeat for all links

Production Images (from

Blog)

|

30th July

|

|

|

13th august

|

|

Evaluate

Aspects of Design –

Function. Based on your calculations critically

evaluate your vehicle’s performance and comment on the effectiveness of

your solution? What is not good or in need of attention with regard to your

solution?

Future improvements – State any

improvements that could be made if you had the opportunity to redesign the

solution i.e. ways to further eliminate friction and resistance forces.

Other vehicles: Comment on the

successes and / or failures of other vehicles.

Subscribe to:

Posts (Atom)